Managing chaos versus and preventing chaos—which would you rather do? You can’t always foresee or prevent disruption; however, if you do see trouble coming, making moves to proactively manage the situation is SMART and can prevent headaches.

Managing chaos versus and preventing chaos—which would you rather do? You can’t always foresee or prevent disruption; however, if you do see trouble coming, making moves to proactively manage the situation is SMART and can prevent headaches.

Read on to discover a few ways that reusable SteriTite® sterilization containers can keep your department on schedule and bring efficiencies beyond those possible with other containers (and certainly with wrap).

Reduce dependence on wrap

If you’re at one of the facilities dealing with wrap orders filled at 80% allocation, you know that running just 80% of surgeries IS NOT an option. The most straightforward insurance policy against wrap shortfalls is a selection of rigid reusable containers. Keep some in inventory for your most frequently used sets or keep some on hand for loaner drop ins.

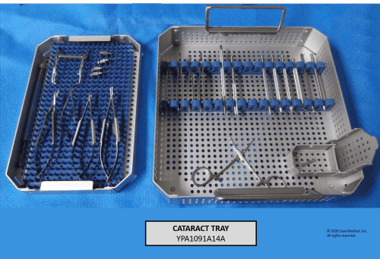

Remember, SteriTite containers are universal, thus you can use the same container for steam or low temperature sterilization. Want to speed up the process? Use our paper filters in our perforated bottom container and save up to 20 minutes of dry time. Consider our customization options for processing complex sets. When there’s a place designated for each instrument, it’s easy to identify whether the set is complete.

Simplify loaners and turnarounds

Some of the most challenging and wrap-intensive sets are those that walk through your front door 48 hours before a surgery—loaner sets. In particular, heavy ortho/spine sets use the largest volume of wrap and often include a complete set of duplicates, a wasteful but necessary process when using wrap, to avoid reprocessing in case of tears.

Any sets that are turned frequently can be good candidates for containerization. The benefit is twofold: save time in prep and pack and save money by eliminating the cost of wrap, indicator tape, corner protectors, and any other accessories. FYI—a frequently turned set will give you the quickest returns.

Cut down on dry time

SteriTite containers, when used with our paper filters in steam sterilization cycles, have FDA 510(k) clearance for minimum 5- to 8-minute dry times. No other container system can deliver such efficient dry times! Specifics are indicated below.

“SteriTite® containers…may be used for storage and transport after steam sterilization with a reduced dry time. Dry loads will be achieved using a minimum of 5 minutes dry time when using perforated bottom units and a minimum of 8 minutes dry time when using solid bottom units.”

“SteriTite® containers…may be used for storage and transport after steam sterilization with a reduced dry time. Dry loads will be achieved using a minimum of 5 minutes dry time when using perforated bottom units and a minimum of 8 minutes dry time when using solid bottom units.”

All with an improved environmental footprint

If your facility measures sustainability initiatives, you’ll want to share this information. According to one source, the healthcare industry discards 255 million pounds of blue wrap each year. Switching to containers helps your facility reduce waste. Over a 10-15 year container life span, that really adds up. Choosing paper filters for steam cycles helps minimize dry times and reserves polypropylene filters for low temperature cycles, when polypropylene is in demand for wrap and PPE. Importantly, paper filters are sustainable.

If your facility measures sustainability initiatives, you’ll want to share this information. According to one source, the healthcare industry discards 255 million pounds of blue wrap each year. Switching to containers helps your facility reduce waste. Over a 10-15 year container life span, that really adds up. Choosing paper filters for steam cycles helps minimize dry times and reserves polypropylene filters for low temperature cycles, when polypropylene is in demand for wrap and PPE. Importantly, paper filters are sustainable.

If you’d like to prevent further disruption in your department, and reduce your dependence on sterilization wrap, contact us at [email protected] and break free. Inquire about our filter, seal, and load card special for increased savings via an automated delivery plan.